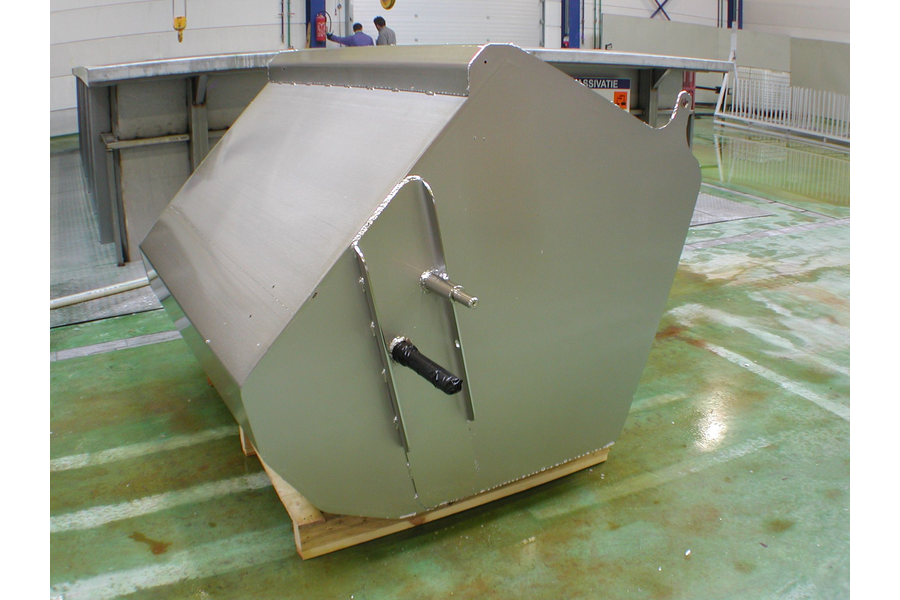

Pickling & Passivation

An essential treatment for stainless steel

Stainless steel is a composition of mostly iron, chrome, nickel and some other elements and impurities. During the production processes impurities may form carbides and make the stainless steel prone to corrosion.

Stainless steel is a composition of mostly iron, chrome, nickel and some other elements and impurities. During the production processes impurities may form carbides and make the stainless steel prone to corrosion.

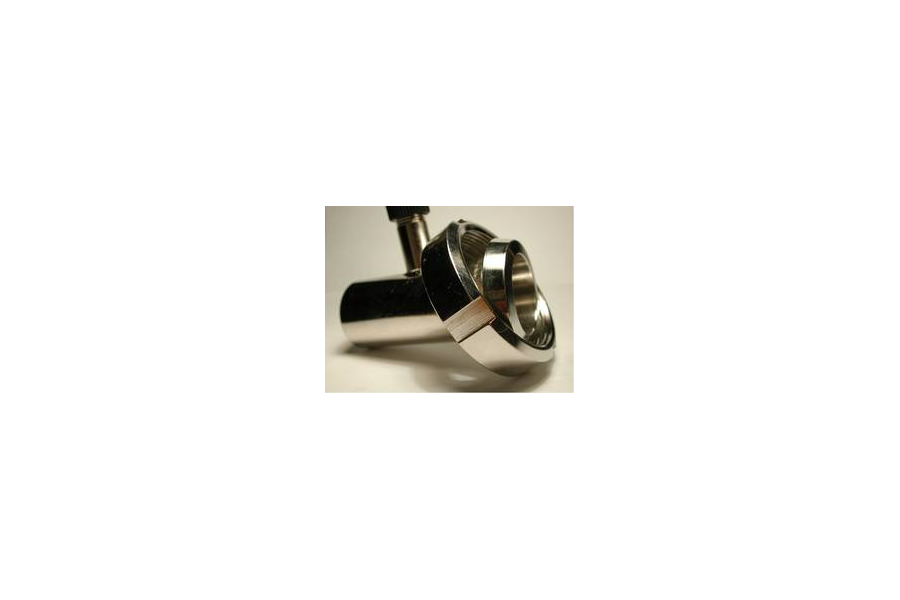

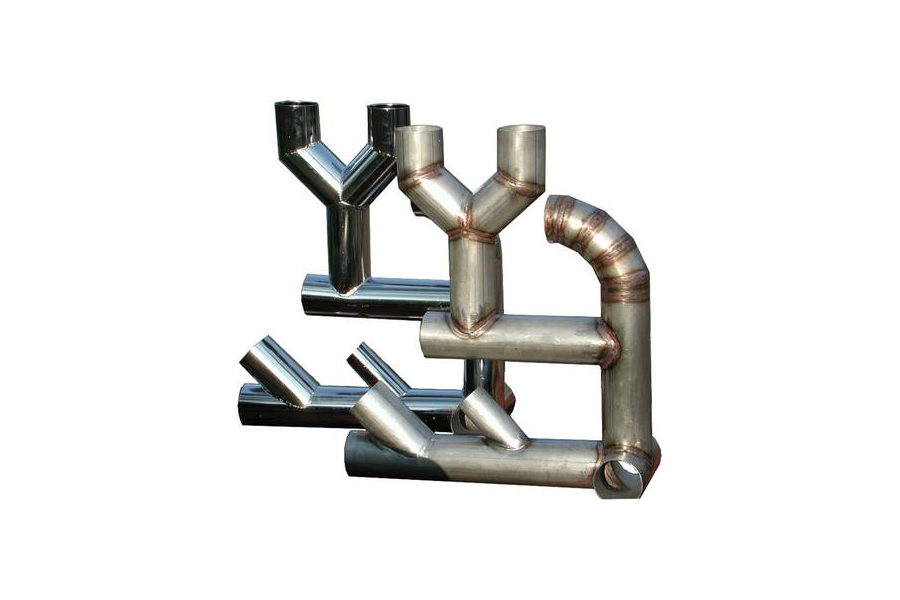

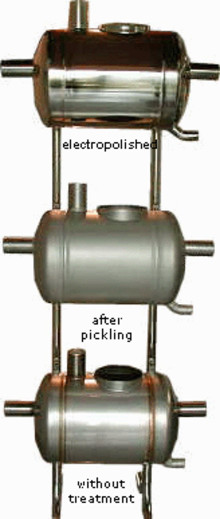

Due to mechanical polishing, milling, machining, welding and other heat treatments, the original austenitic structure is lost. In this case the stainless steel loses its ability to spontaneously form its protective oxides. Therefore it is necessary to clean the stainless steel from impurities after these operations.

This can be done with a mix of acids, which dissolve impurities and imprinted iron particles, and make welding discoloration go away.

A thick protective, sealing oxide skin is the result of this passivation method. The stainless steel regains its original corrosion resistance properties and shows a soft grey satin grey finish.

White Pickling

Packo Surface Treatment executes pickling and passivation of stainless steel according to just about any desired standard or procedure; ASTM, MIL, MIT, DIN, ISO, EN, etc...

You can choose between spray pickling, immersion pickling, localised pickling, anodic pickling, mechanical pickling, acid-free pickling, ecological pickling, ...